Select an icon to see the benefit

For super strength long lasting repairs to concrete floors, ramps & steps

| Quantity | Price per item | Discount |

|---|---|---|

| 1+ | £120.40 | - |

| 6+ | £114.50 | Save 5% |

| Bulk discounts applied in basket | ||

This product option is unavailable, please make an alternative selection.

| Quantity | Price per item | Discount |

|---|---|---|

| 1+ | £120.40 | - |

| 6+ | £114.50 | Save 5% |

| Bulk discounts applied in basket | ||

Following extensive research and formulation development, we've launched our best ever epoxy repair mortar, Concrex Carbon Fibre. The improved repair mortar has joined the extensive Concrex range, replacing the bestselling original formulation to achieve even greater results.

Concrex Carbon Fibre is a premium epoxy resin mortar designed to permanently repair damaged concrete floors. The carbon fibre and ceramic based formulation is now even stronger, more chemical resistant and dries even faster.

Simple to use, it's already part mixed with the resin and aggregate combined, further reducing preparation time. Simply add the grey activator to the mix (this is coloured to help users ensure it is sufficiently combined) and the product is ready to go.

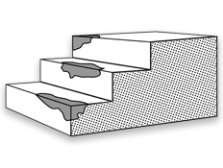

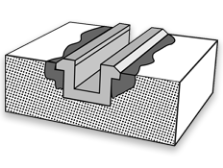

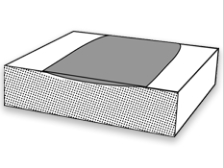

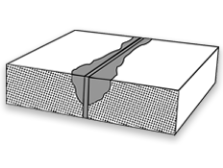

Concrex Carbon Fibre is versatile enough for use across a wide range of environments. It can be used virtually anywhere an ordinary mortar might fail, including holes, guide rails, ramps, steps and spalled joints. The revamped mortar can also be 'moulded' into shape to form a kerb and even repair step nosing. Most repairs using Concrex Carbon Fibre require no primer but it can be used with Watco's Tack Coat for intricate repairs, or thin screeding jobs.

Damaged steps

Fitting guide rails

Worn floors

Expansion joints

Different levels

Holes

Benefitting from recent advances in resin technology and access to new raw materials, our chemists have devised a powerful solution that delivers stronger, faster and longer-lasting performance than anything that has come before.

"By blending carbon fibre and ceramic into this formulation, we have enhanced the performance of what was already the number one best-selling epoxy repair mortar on the market, providing Watco customers with the ultimate solution that cannot be beaten".

Chris Budd, Product & Operations Director

Concrex® Carbon Fibre is the ultimate floor repair mortar. Based on our best-selling Concrex, the addition of Carbon Fibre, ceramic and an increase in resin content makes this the strongest, longest lasting epoxy floor repair mortar that you can buy. To prove it, Concrex Carbon Fibre now comes with a 20-year guarantee against impact and abrasion failure. Its unique formulation outperforms the original Concrex - already the strongest on the market - for strength, drying time, and chemical resistance. What's more, its stronger, longer lasting and will out perform any cement based alternative.

For over 50 years, the Concrex® brand has been the leading epoxy repair mortar and millions of kilos of it are reinforcing and protecting concrete floors, steps and ramps across Europe and the rest of the world. All Concrex Carbon Fibre repairs should be considered permanent, which is why it's our benchmark for repairing concrete floors. Its a versatile formulation that provides a granite-hard finish that is impervious and non-dusting. After all, it’s what you should expect from the number one epoxy repair mortar.

Coverage: Approx. 1.2m² per 10kg at 5mm thick

Did you know you can receive everything you need for your repair and save money with our Concrex bundle?

| Properties | Incredibly tough, granite–hard finish, chemical–resistant, anti–slip, priming not normally required, impervious and non-dusting, may be feather-edged, ready for heavy traffic in 4 hours |

| Suitable for | Floors, ramps, steps |

| Finish | Smooth, impervious surface |

| Interior or Exterior | Exterior, Interior |

| Primer required | Yes, Watco Tack Coat is recommended |

| Composition | Two part epoxy resin |

| Coverage | 3m² per 25kg |

| Application tools | Trowel or float |

| Application | Trowel the mortar firmly into the repair |

| Curing time (at 20°C) | 1 hours |

| Maximum operational temperature | 60°C |

| Pot life | 30 minutes |

| Depth | 50mm |

Surfaces to be treated must be clean, dry and free of all loose material. Wire brushing or sweeping is usually sufficient. Watco Bio-D degreaser can be used if there are spots of oil or grease. If the surface is damp it can be primed with Watco Tack Coat.

The resin content of Watco Concrex® Carbon Fibre is very high. This means that a primer is not usually required when filling holes in concrete floors or resurfacing rough or damaged concrete. Watco Tack Coat adhesive primer is recommended when using Concrex® Carbon Fibre as a thin section screed over smooth surfaces. It is also recommended when repairing intricate/high impact areas such as broken floor joint edges, and damaged step nosings.

Each bucket contains Concrex powder and bottles of curing agent. Mix the two components with a trowel until you achieve a uniform grey colour, you can complete the mixing by using your gloved hands. For large quantities, it is advisable to use a mixer.

Apply the repair mortar to the surface to be repaired and smooth with a trowel. To prevent streaks, wipe the blade with a rag soaked in white spirit.

Extensive testing is what makes us the most highly qualified paint and repair manufacturer on the market. Our screeds and repair products are tested in areas of tensile, compressive strength and flexural strength.

Concrex is far stronger than concrete, we don’t need to say it, we can prove it. Here’s a comparison:

| Watco Concrex | Concrete | |

| Tensile Strength | 15.4 MN | 3.4MN |

| Flexural Strength | 55.9MN | 6.9MN |

| Compressive Strength | 55.2MN | 21.41MN |

Learn more about the tests we carry out and how to read the results here

Full test results can be found on the Technical Data Sheet

|

|

|

|

|

|---|---|---|---|---|

|

This product:

Watco Concrex® Carbon Fibre - Epoxy Repair Mortar |

Watco Concrex Asphalt Repair |

Watco Bitu-Mend® Pothole Repair |

Watco Flowpatch |

|

|

From £120.40 (Ex VAT) |

£254.20 (Ex VAT) |

From £71.70 (Ex VAT) |

From £64.50 (Ex VAT) |

|

|

Please make a product selection to continue |

View | View | View | |

| Composition | Two part epoxy resin | 2 part epoxy resin plus aggregate | Single pack bitumen & aggregate blend | Reinforced cement & polymer powder |

| Durability | Extreme | Extreme | Heavy | Heavy |

| Suitable for asphalt & concrete | Concrete | Concrete | ||

| Deep fill version available | ||||

| How applied | Trowel | Trowel | Shovel and tamper | Pour |

| Cold setting version available | - | - | ||

|

Please make a product selection to continue |

View | View | View |

Our chemists have developed cold curing products with the latest resin technology so you can continue with your repair projects all year round.

All cold cureOur Deep Fill alternatives allow you to apply them at much thicker depths in one application. Meaning you can get a more economical formula that delivers the same strength and reduces downtime.

All hole repairFlexible formulations are ideal for areas where vibration, movement or impact may occur. The material moves with the substrate to avoid it breaking up or cracking.

All flexibleIf you are repairing an asphalt substrate, then we have a range of bitumen based products that help blend in with the existing environment.

All asphalt repairif you are repairing an area where chemicals are stored or regularly used, you will need to ensure the repair material can stand up to chemical attack.

All chemical resistanceThis product option is unavailable, please make an alternative selection.