Heathrow Airport Hounslow, UK

Airport

Durability

Anti Slip

Minimal downtime

In March 2008, London’s Heathrow Airport opened a brand-new terminal to meet the significant demand for international travel. The £4 billion facility, Terminal 5, was developed to accommodate upwards of 30 million passengers each year.

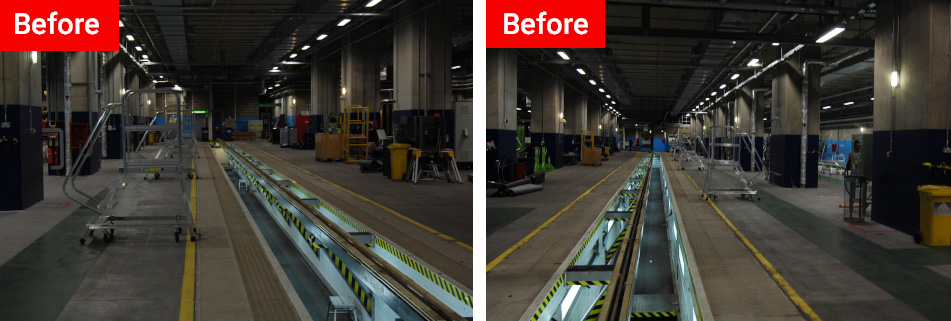

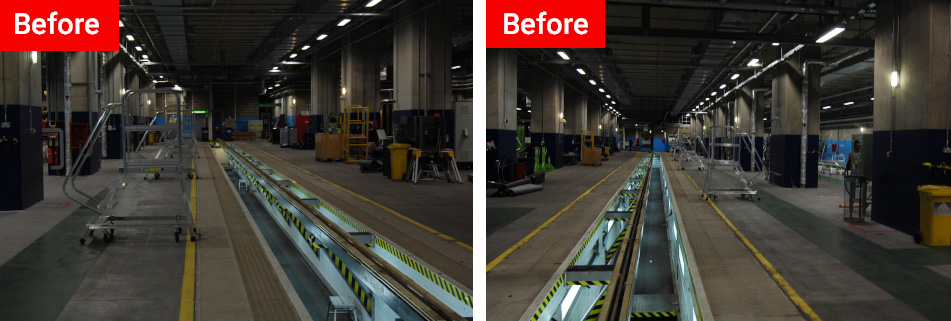

The busy airport terminal operates a driverless track transit system to transport passengers between its T5A, T5B and T5C buildings. With hundreds of flights taking off across the terminal each day, it is crucial that the transit system is running safely and smoothly. With ongoing inspection and maintenance conducted for the tracks, shuttles and workshop where shuttles are housed each night.

A C Beck, the decorating specialists, were awarded a contract to update the design of the shuttle workshop and ensure a safe operating environment. Having previously collaborated on successful projects, A C Beck selected Watco’s expert team to advise on the project and provide the products required to transform the space.

Following a visit to the terminal’s shuttle workshop to draw up a specification, Watco’s experts invited the project team to a training session at its headquarters in Guildford to discuss the product specifications then align on the selection and approach.

It was quickly identified that to ensure a safe space for those working in such close proximity to operational shuttle tracks, the coating selected would need to incorporate anti slip properties. Additionally, in response to the high level of foot traffic in the workshop day-to-day, the coating would need to ensure that the anti slip surface would not quickly become prone to deteriorate through wear.

The operational tracks proved a consideration for the project’s logistics too, since the shuttle system would not be shut down during the project. Therefore, downtime had to be carefully considered to ensure minimal disruption when the shuttles would arrive into the workshop each night.

“With hundreds of flights taking off across the terminal each day, it is crucial that the transit system is running safely and smoothly”

After the group training session in Guildford had taken place and product selection was aligned, Watco’s experts began by applying Concroff, a high-performance cleaner and degreaser, to remove any surface contaminants and prepare the concrete for application.

Once cleaned and prepared, a coat of Epoxicote High Build Mid Green was applied to the concrete. The 100% solids epoxy resin coating was selected due to its hard-wearing and chemical resistant properties, which were required to withstand the nightly high volume of traffic in the workshop and the chemical-based products used in shuttle repair and maintenance.

Upon applying the second coat of Epoxicote High Build, coarse white grit was applied to the wet coating before being swifty rolled again to colour the grit green and bed it into the surface. The grit and epoxy resin coating combined would offer a durable, hard-wearing anti slip solution for those operating in the workshop – supporting a safer environment around the live shuttle tracks. In accordance with the project’s requirement for minimal downtime, an accelerator was also used to speed up the curing time.

Following the successful application in the first stage of the project, A.C Beck also chose Watco to advise and supply the products for their line marking, which was required to produce a safety zone from the high voltage power line. Watco’s Epoxicote High Build in Safety Yellow was selected and applied to provide excellent wear, abrasion resistance and strong visibility from the first coat.

Stokeford Studios is Sarah Beeny’s latest renovation project, transforming an disused barn into a multi-purpose studio for art, music, film and tv.

Heathrow, the UK's biggest airport, embarked on a project to update the design of their shuttle workshop and enlisted the help of Watco’s expert team to transform the space.

Tanhurst Estate raises a glass to Watco's concrete floor solutions. Saving them time which can be to spent making good wine!

Paradise Wildlife Park, situated in Hertfordshire contacted Watco for advice on a floor paint suitable for their lion enclosure.

The Midtown cycle vault created by Cyclehoop were looking for an epoxy paint which would be long lasting and could cope well with heavy traffic

Watco GRP Decking Strips provide safety to a top college in Surrey, where slippery decking was becoming a safety concern to staff and students.