Download our FREE guide to concrete floor repairs

In this guide you will discover...

- Why is floor repair essential?

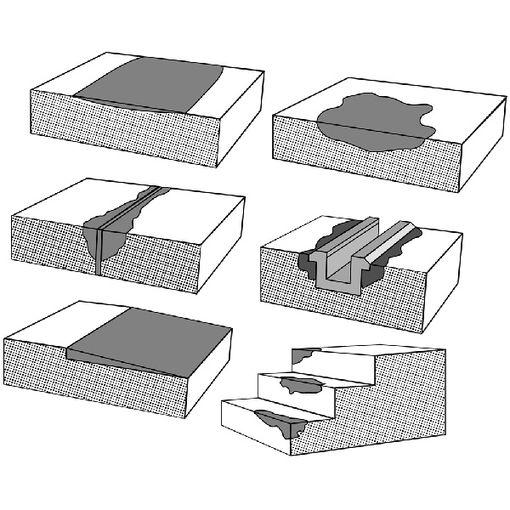

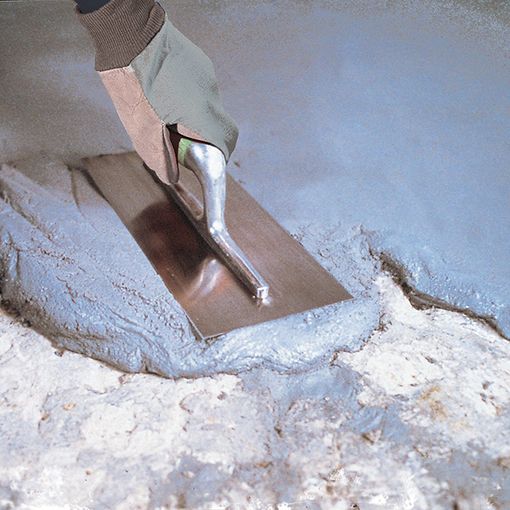

- Different types of damage and how to repair them

- General surface repairs, cracks, joints, steps, resurfacing and more

- How Watco can help you with your repair projects