Select an icon to see the benefit

Extra thick for heavy traffic areas in warehouses, garages, receptions, oil & chemical areas

| Quantity | Price per item | Discount |

|---|---|---|

| 1+ | £198.70 | - |

| 6+ | £178.80 | Save 10% |

| Bulk discounts applied in basket | ||

| Quantity | Price per item | Discount |

|---|---|---|

| 1+ | £198.70 | - |

| 6+ | £178.80 | Save 10% |

| Bulk discounts applied in basket | ||

For best results, thoroughly clean and prepare the floor prior to painting to ensure surface laitance, dust, dirt and grease are removed. We recommend Epoxicote High Build Primer for bare concrete surfaces as it will prevent air bubbles from forming and will promote good adhesion on hard, smooth or powerfloated concrete floors.

Remove the two inner tins from the tall outer tin, stir thoroughly and pour into the tall outer tin. Mix all components thoroughly. Once all the components have been mixed, a chemical reaction takes place. The product should therefore be decanted into a shallow tray and used straight away.

Apply one coat with a medium pile roller, working well into the surface of the concrete. Best results are obtained in warm, dry conditions with good ventilation.

This two part, 100% solids epoxy resin formula provides superior and long lasting protection to heavily trafficked areas. Easy to apply and with multiple colours to choose from, one thick coat is enough to create a glossy and strong finish that offers excellent chemical resistance to warehouses, garages, receptions, and oil & chemical areas.

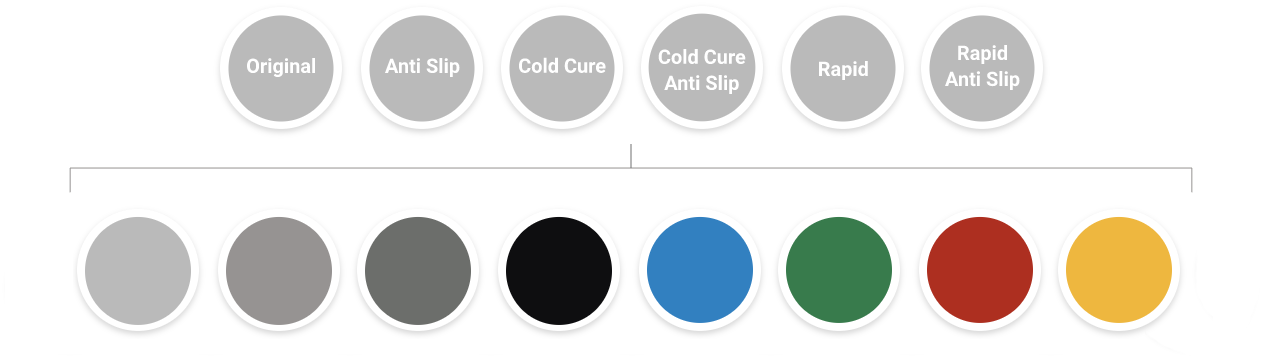

Watco Epoxicote High Build comes in several finishes to give your floor the ultimate protection it deserves. Choose from original, Anti Slip, Cold Cure, Cold Cure Anti Slip, Rapid and Anti Slip Rapid. And it also comes in a variety of colours. Making it the ideal choice for heavy duty floor paint protection.

Watco Epoxicote High Build comes in several finishes to give your floor the ultimate protection it deserves. Choose from original, Anti Slip, Cold Cure, Cold Cure Anti Slip, Rapid and Anti Slip Rapid. It also comes in a variety of colours. Making it the ideal choice for heavy duty floor paint protection.

Epoxicote High Build Primer

With one simple coat, the Primer quickly smoothes bare concrete floors, which would otherwise reject a paint coating. This eliminates the need for grinding or costly shot blasting. As the Primer completely seals porous concrete, no air bubbles will appear in the thick, glossy and strong coating from the High Build.

Epoxicote High Build

The high build coating provides superior and long-lasting protection. Easy to apply and with multiple colours to choose from, one thick coat is enough to create a glossy and strong finish that offers excellent chemical resistance to warehouses, garages, receptions and oil and chemical areas.

Formulating paints and coatings that can withstand even the toughest of environments is what our chemists do best. A big advantage of this formulation is it does not need water to make it cure. Instead a chemical reaction takes place after the base and activator are mixed together, which brings about rapid drying. This makes the product suitable for areas where there is poor ventilation, cold temperatures or high humidity.

| Suitable for | Concrete, well bonded paint, some metals |

| Finish | Glossy, smooth |

| Interior or Exterior | Interior |

| Primer required | On bare concrete. See ‘Priming’ section in ‘Application’ |

| Composition | 2 part, 100% solids epoxy resin |

| Number of components | 1 x curing agent and 1 x resin |

| Coverage | 18m² per 4L |

| Recommended number of coats | 1 |

| Mix ratio | 100 parts resin : 24 parts curing agent |

| Wet film thickness | 220 microns |

| Dry film thickness | 220 microns |

| Curing time (at 20°C) | 16 hours |

| Minimum application temperature | 15°C |

| Pot life | 25 minutes at 20°C |

| Shelf life | 24 months in unopened container |

| Cleaning tools | It is not practical to clean applicators and they should be discarded after use |

Bare Concrete – remove surface laitance, dust and any light dirt or grease deposits using Watco Etch & Clean. Watco Etch & Clean also etches smooth, bare concrete surfaces to provide a key. Flush with clean water and allow surface to dry. For the removal of heavier deposits of oil and grease we recommend Watco Concroff, again, flush with clean water and allow the surface to dry.

New Concrete – as a guide, new concrete should be left for eight weeks to dry (if the application has to go ahead before this, use Watco New Concrete Primer). The surface should then be prepared using Watco Etch & Clean and thoroughly rinsed away and left to dry prior to applying this coating.

Priming – Watco Epoxicote High Build Primer is recommended for bare concrete surfaces. It prevents air bubbles forming in Epoxicote High Build when painting open textured or porous concrete. Using this primer also promotes good adhesion when painting hard, smooth or power floated concrete.

Painted surfaces – abrade to remove any weak or loose paint. Check remaining paint is well bonded. Very smooth, glossy paint should be lightly abraded to provide a key. Watco Bio D can be used to remove grease and oil from painted surfaces. Watco Concroff is a very powerful degreaser for contaminated bare concrete, do not use on a previously painted surface since it can soften paint.

Metal – remove any rust and flaking material by disc grinding or wire brushing. Apply the coating immediately after Preparation to the clean metal surface. Grease or oil can be removed using Watco Bio D. Allow the metal to dry before coating.

Galvanised Metal – Watco Galvaprime must be used to prepare galvanised metal.

Non-ferrous Metals - for advice, please contact our Technical Department.

Remove the two inner tins from the tall outer tin. Stir the contents of each tin thoroughly and pour all of the contents into the outer tin, (scrape around the inside of the tins to remove any residue). Mix the components together thoroughly using a spatula or similar wide bladed tool, (a piece of wooden batten is ideal) and do not thin. Continue mixing until an even colour and consistency are obtained. Do not mix more than one pack at a time. If a paint stirrer fitted to an electric drill is used, also use the spatula to blend in any unmixed material from the sides and bottom of the tin. In the anti slip versions the slip resistant particles are already pre-blended (in the Curing Agent).

Important - once the contents of the pack have been mixed, a chemical reaction takes place which creates heat. The product should therefore be decanted into a shallow tray to avoid reducing the pot life and used straight away. Best results are obtained in warm (minimum of 15°C), dry conditions with good ventilation. Apply one coat with a medium pile roller, (not foam), working well into the surface of the concrete. On vertical surfaces 2 thin coats are recommended. Do not exceed the maximum coverage of 18m² per 4L pack. Do not wash or allow water to lie on the surface for at least 7 days.

Extensive testing is what makes us the most highly qualified paint and repair manufacturer on the market. Our tests cover just about everything you might want to know about a floor coating – how well it bonds to the floor, how durable it is, how well it stands up to scratching and much more.

The test results for Epoxicote High build really do put it in a class of its own:

Learn more about the tests we carry out and how to read the results here

Full test results can be found on the Technical Data Sheet

|

|

|

|

|

|---|---|---|---|---|

|

This product:

Watco Epoxicote High Build |

Watco Epoxy Gloss Coat |

Watco Fastcoat |

Watco Resiflow |

|

|

From £198.70 (Ex VAT) |

From £161.30 (Ex VAT) |

From £151.70 (Ex VAT) |

From £186.45 (Ex VAT) |

|

|

Please make a product selection to continue |

View | View | View | |

| Composition | 2 part, 100% solids epoxy resin | 2 part reinforced water based epoxy resin | 2 part polyaspartic resin | 2 part, 100% solids epoxy resin |

| Durability | Very heavy | Heavy | Very heavy | Exceptionally heavy |

| Dry film thickness | 220 microns | 100 microns | 85 microns | 1.5mm |

| Chemical Resistant | Excellent | Good | Good | Very good |

| Interior or Exterior | Interior | Interior | Exterior, Interior | Interior |

| Finish | Glossy, smooth | Glossy, smooth | Glossy, smooth | Glossy, smooth |

| Recommended number of coats | 1 | 2 | 2 | 1 |

|

Please make a product selection to continue |

View | View | View |

Chemical resistance is important for areas that store or use chemicals. To protect the surface and increase its longevity, you’ll need a coating that stands strong against chemical spills.

All chemical resistanceOur chemists have developed cold curing products with the latest resin technology so you can continue with your repair projects all year round.

All cold cure

Extra thick for heavy traffic areas in warehouses, garages, receptions, oil & chemical areas

From £198.70 (Ex VAT)

A thick 'high build' anti slip coating for exceptional wear protection. For heavy traffic areas

From £211.60 (Ex VAT)

A thick virtually solvent free epoxy. One coat protection for heavily trafficked surfaces

From £211.60 (Ex VAT)

The ultimate rapid setting high build epoxy resin floor coating for interior concrete

From £211.60 (Ex VAT)

A fast drying thick 'high build' paint for heavy traffic areas. Cures in 8 hours.

From £218.00 (Ex VAT)

Our thick 'high build' anti slip coating for heavy traffic areas - with cold curing ability

From £218.00 (Ex VAT)