UK

Factory

User friendly products

Rapid curing

Create clear line marking

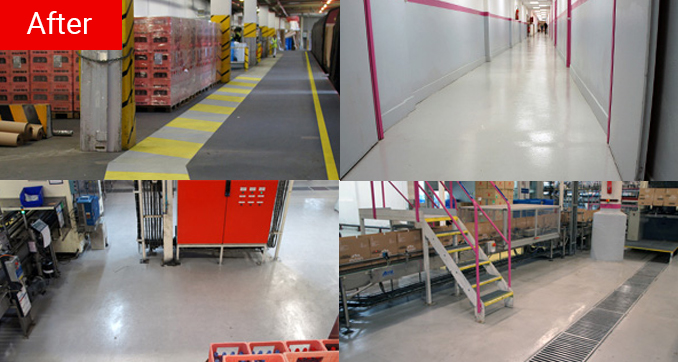

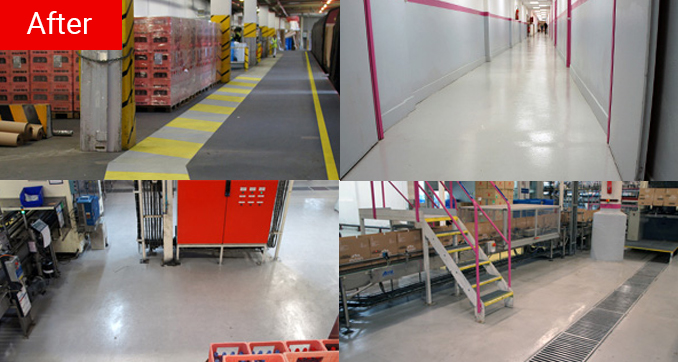

Watco worked with the world’s second largest producer of bottled water, to renovate and revitalise its factory space.

Food processing plants must adhere to strict environmental and safety regulations in order to facilitate a safe and productive work environment. The bottled water company was particularly conscious of the hazards created by its busy factory floor, and the importance of using methods such as line marking to help avoid the accidents that frequently arise in these environments.

Following an internal review of the site, it was identified that floor markings were no longer visible for team members to follow, and cracks were beginning to appear in the floor which increases the risk of trips and falls. As a result, the bottled water company began looking for solutions and suppliers to transform the space.

Efficiency was an important consideration for this renovation, with a goal to use industrial floor paints in order to create seamless traffic flows through its factories - a total coverage area of 2500m².

Furthermore, as a business with a very close working team, the client insisted on the involvement of its teams in completing the renovations, from the accounting department to the technical teams. This was a great fit for Watco’s products which have been crafted for user-friendly applications. Therefore, the paints and coatings could be applied easily and safely by all of the staff involved. The client was also able to use the time spent renovating, to highlight important safety considerations within the workspace to the entire team.

In order to minimise downtime and disruption to the global operations, the Watco experts were also able to recommend solutions which would adhere to the regulations but also have a rapid curing time.

Efficiency was an important consideration for this renovation, with a goal to use floor paints in order to create seamless traffic flows through its factories.

Following comprehensive research of the solutions available on the market, the bottled water giant selected the long lasting, user-friendly products from Watco – sharing that the options really stood out from the competition.

After assessing the factory’s needs and taking into account the safety requirements of the project, Watco’s experts recommended the application of Safety Grip, a heavy duty, anti slip epoxy resin coating. This product, which is slip resistant even when wet or oily, helped to minimise the risk of slips trips and falls on the factory floor, helping to create a safer workspace for employees.

Epoxyline, a heavy duty, fast-drying, line marking paint was also recommended for this renovation, due to its perfect fit to requirements. Restoring faded line markings on the factory floor and making sure that walkways were clearly defined was a key objective within the project to ensure that traffic could flow but also that employees would follow marked paths and avoid dangerous areas. The product’s fast-drying element also helped minimise factory downtime, so that regular operations could resume as quickly as possible.

Finally, Epoxy Gloss Coat was recommended by experts, due to its virtually solvent-free nature which was ideal for a food processing plant. The solution is an extremely durable floor coating and was therefore particularly suitable for a high-traffic factory floor.

Heathrow, the UK's biggest airport, embarked on a project to update the design of their shuttle workshop and enlisted the help of Watco’s expert team to transform the space.

Tanhurst Estate raises a glass to Watco's concrete floor solutions. Saving them time which can be to spent making good wine!

Paradise Wildlife Park, situated in Hertfordshire contacted Watco for advice on a floor paint suitable for their lion enclosure.

The Midtown cycle vault created by Cyclehoop were looking for an epoxy paint which would be long lasting and could cope well with heavy traffic

Watco GRP Decking Strips provide safety to a top college in Surrey, where slippery decking was becoming a safety concern to staff and students.

A well-known kitchen appliance manufacturer chose Watco products as a solution to dusty concrete floors.